Indlela ye-PVC ye-calendering yomgangatho yinkqubo yokuvelisa esebenzayo neqhubekayo, elungele ngokukodwa ukuveliswa kwamaphepha esakhiwo alinganayo kunye ne-permeable (efana norhwebo lwe-homogeneous permeable flooring). Undoqo wayo kukwenza iplastiki yePVC etyhidiweyo ibe ngumaleko obhityileyo ofanayo ngokusebenzisa i-multi-roll calender, uze uyipholise ukumila. Oku kulandelayo ngamanyathelo athile kunye neendawo eziphambili zolawulo lobugcisa:

I. Inkqubo yokuKhalenda

Unyango lwangaphambili lweMathiriyeli ekrwada > Ukuxuba okushushu okukhawulezileyo, ukupholisa nokubandayo, ukuxutywa kwangaphakathi kunye neplastiki, ukuxutywa okuvulekileyo kunye nokutyisa.

I-4-roll calendering, i-embossing / laminating, ukupholisa kunye nokubunjwa, ukucheba kunye nokujika

II. Amanqaku aphambili okusebenza ngamanyathelo kunye neeParameters zobuGcisa

1. Ukulungiswa kwangaphambili kwezinto ezikrwada kunye nokuxuba

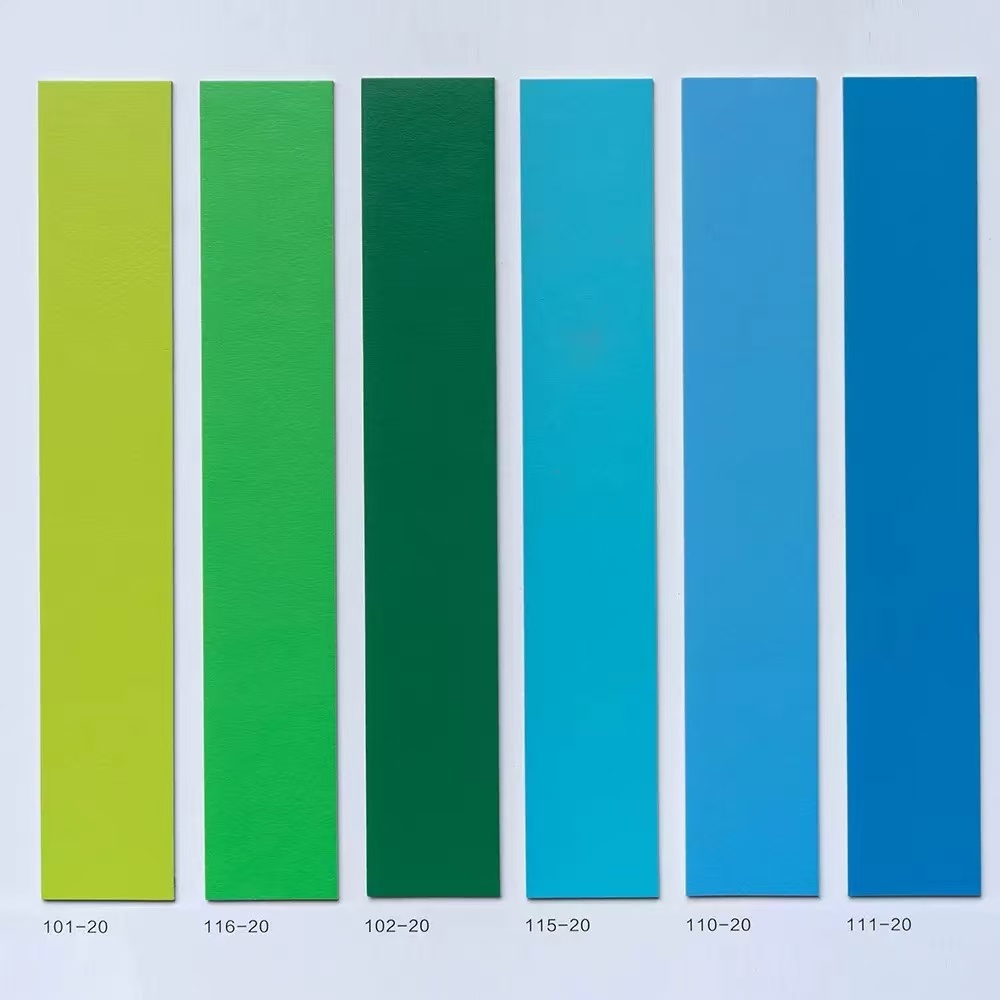

Ukuqulunqwa kweFomula (Umzekelo): - I-resin ye-PVC (uhlobo lwe-S-70) iinxalenye ze-100, - I-Plasticizer (i-DINP / i-ester enobungane ngokwendalo) iinxalenye ze-40-60, - I-Calcium carbonate filler (i-1250 mesh) iinxalenye ze-50-80, - I-Heat stabilizer (i-calcium zinc composite, i-lubricant ye-calcium, i-3-5 inxalenye ye-asidi) - I-pigment (i-titanium dioxide / i-inorganic color powder) iindawo ezi-2-10

Inkqubo yokuxuba*:

Ukuxuba okushushu: Umxube wesantya esiphezulu (≥1000 rpm), ukushisa kwi-120 ° C (imizuzu eyi-10-15) ukuvumela i-PVC ukuba ithathe i-plasticizer; Ukuxuba Okubandayo: Ukupholisa ngokukhawuleza ukuya ngaphantsi kwe-40 ° C (ukuthintela amaqhuma), ixesha lokuxuba elibandayo ≤ imizuzu eyi-8.

2. Ukwenza iPlastiki kunye noKutyisa

- Umxubi wangaphakathi: Ubushushu 160-170 ° C, Uxinzelelo lwe-12-15 MPa, Ixesha le-4-6 imizuzu → Ukwenza i-rubber mass ye-homogeneous;

Vula Umxube: Ubushushu be-Twin-roll yi-165±5°C, i-Roller Gap 3-5 mm → Sika ube yimicu ukwenzela ukondliwa ngokuqhubekayo kwikhalenda.

3. Ii-Calender ezine-roller (Inkqubo engundoqo)

-Ubuchule obuphambili:

- Roller Speed Ratio: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (ukuthintela ukuqokelelana kwezinto);

- Imbuyekezo yoBubude obuphakathi: I-Roller 2 yenzelwe isithsaba se-0.02-0.05mm ukucima i-thermal bending deformation. 4. Unyango loMphezulu kunye nokuLamination

I-Embossing: I-roller ye-Embossing (i-silicone / insimbi) ukushisa kwe-140-150 ° C, uxinzelelo lwe-0.5-1.0 MPa, isantya esihambelana nomgca we-calendering;

I-Substrate Lamination (Ngokuzikhethela): I-glass ye-fiber mat / ilaphu elingalukiweyo, i-preheated (100 ° C), i-laminated kunye ne-PVC inyibilika kwi-roller #3 ukuphucula ukuzinza kwe-dimensional.

5. Ukupholisa kunye nokuBunjwa

Ubushushu berola enezigaba ezithathu:

Ulawulo lweTension: Uxinzelelo lomoya 10-15 N/mm² (ukuthintela ukushwabana okubandayo kunye nokonakala).

6. Ukucheba kunye nokuQhuba

-I-Laser Online yokulinganisa ubutyebe: Ingxelo yexesha langempela ilungisa i-gap ye-roller (ukuchaneka ± 0.01mm);

- Ukunquma ngokuzenzekelayo: Ububanzi be-Scrap ≤ 20mm, ihlaziywe kwaye ifakwe kwi-pelletized ukuze iphinde isetyenziswe;

- Ukugquma: Ukujija rhoqo kwiziko loxinzelelo, i-rolling diameter Φ800-1200mm. III. Ubunzima beNkqubo kunye nezisombululo

1. Ukutyeba okungalinganiyo. Unobangela: Ukutshintsha kobushushu beRola > ±2°C. Isisombululo: I-Loop-Loop evaliweyo yoLawulo loBubushushu be-Oli ye-Oli + i-Cooling-Drilled Roller Cooling.

2. Irhasi yoMphezulu. Unobangela: Ukungonelanga Ukuxutywa kwe-Degassing. Isisombululo: Vacuum uMxubi wangaphakathi (-0.08 MPa).

3. IiNceba zoMda. Unobangela: Ukupholisa Okugqithisileyo / Uxinzelelo Olugqithisileyo. Isisombululo: Nciphisa i-Front-End Ukupholisa ngamandla kwaye Yongeza iNdawo yokuPholisa kancinane.

4. Umzekelo Die. Unobangela: Uxinzelelo lwe-Embossing Roller olunganelanga. Isisombululo: Yandisa i-Hydraulic Pressure kwi-1.2 MPa kwaye ucoce i-Roller Surface.

IV. IiNkqubo eziHlanganisiweyo kokusiNgqongileyo kunye nokuPhuculwa kokuSebenza

1. UTshintsho lokuZinzisa olungaMahla:

- I-Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Ukuphumelela uvavanyo lwe-EN 14372 lokufuduka;

2. Iplastiki yePlastiki ehambelana nokusiNgqongileyo:

- I-DINP (i-Diisononyl Phthalate) → i-Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Yehlisa i-Ecotoxicity.

3. Ukwenziwa ngokutsha kweNkunkuma:

- Iimvuthuluka ezicoliweyo → Ukudibanisa ngemathiriyeli entsha ngokomlinganiselo ≤30% → Isetyenziswa kwimveliso yomaleko wesiseko.

V. Calender vs. Extrusion (Uthelekiso lwesicelo)

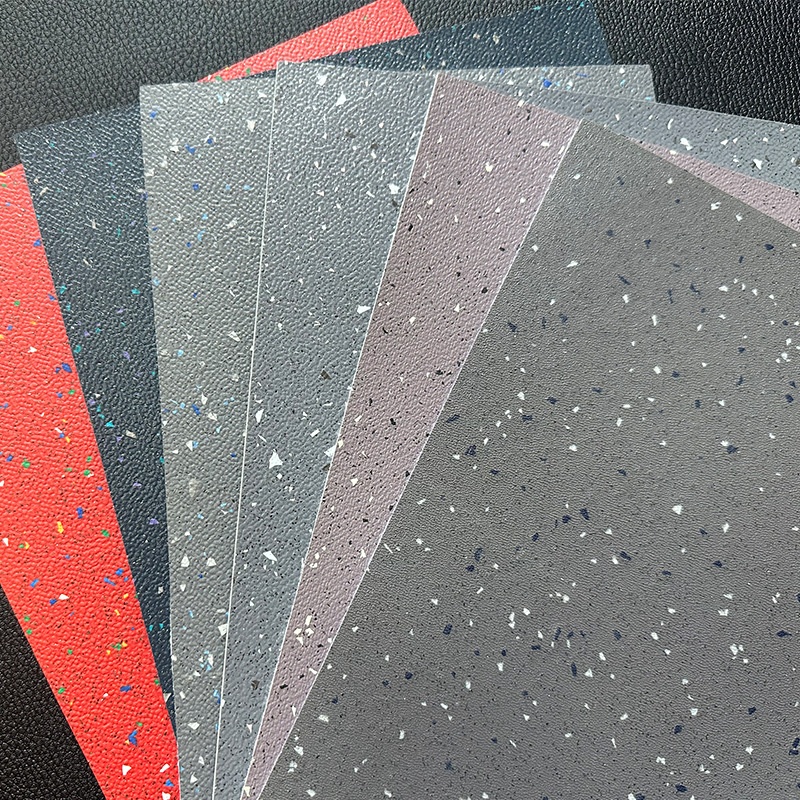

Ulwakhiwo lweMveliso: Umgangatho onemingxuma elinganayo/Uluhlu olunemingxuma emininzi, i-multi-layer co-extrusion (umaleko ongagugiyo + umaleko wegwebu)

Uluhlu lokutyeba: 1.5-4.0mm (Ukuchaneka ± 0.1mm), 3.0-8.0mm (Ukuchaneka ± 0.3mm)

UkuGqiba komphezulu: Iglosi ephezulu/ihombiso echanekileyo (ukulinganisa iinkozo zokhuni), iMatte/Ukwakheka okurhabaxa

Usetyenziso oluQhelekileyo: Imigangatho enemingxuma elinganayo kwizibhedlele nakwiilabhoratri, iSPC evalelanayo imigangatho yamakhaya.

Isishwankathelo: Ixabiso elingundoqo lendlela yokuhlelwa kweekhalenda lisemandleni "kuchaneka okuphezulu" kunye "nokuhambelana okuphezulu"

-Izinto eziluncedo kwinkqubo:

- Ulawulo oluchanekileyo lobushushu berola → ukutyeba ukwahluka komlinganiso <1.5%;

-I-in-line embossing kunye ne-lamination → Phumelela imbonakalo yelitye/yentsimbi;

- IiMveliso eziSebenzayo:

Umgangatho wePVC onemingxuma elinganayo kunye neemfuno zozinzo oluphezulu (ezifana neTarkett Omnisports series);

-Phucula iiKhetho:

- Ulawulo olukrelekrele: uhlengahlengiso lwe-AI-powered dynamic roller gap (ingxelo yobukhulu bexesha lokwenyani);

- UkuBuyiselwa kwakhona kwamandla: Ukupholisa ubushushu benkunkuma yamanzi busetyenziselwa ukufudumeza imathiriyeli ekrwada (konga ama-30% amandla).

> Qaphela: Kwimveliso yangempela, ukushisa kwe-calendering kunye nesantya se-roller kufuneka kulungiswe ngokwe-formula fluidity (i-melt index MFI = 3-8g / 10min) ukuphepha ukuthotywa (i-yellowing index ΔYI <2).

Ixesha lokuposa: Jul-30-2025